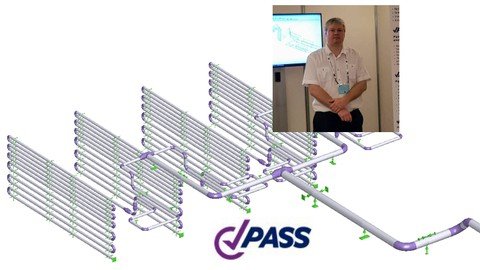

Pipe Stress Analysis Complete Course From Pass

Published 6/2022

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz

Language: English | Size: 12.65 GB | Duration: 24h 56m

Pipe Stress Analysis Basics and Advanced Techniques. For Beginners and for Experienced Pipe Stress Engineers

What you'll learn

Pipe stress analysis theory. Load types. Stress types. Bourdon effect. Creep effect in high temperature piping, creep rupture usage factor (Appendix V ASME B31.

ASME B31.1, ASME B31.3, ASME B31.4, ASME B31.5, ASME B31.8, ASME B31.9, ASME B31.12 code requirements for pipe stress analysis

How to use PASS/START-PROF software for pipe stress analysis

How to work with different load cases

How to model different typs of piping supports, spring selection

What is stress intensification and flexibility factors and how to calculate them using FEA and code requirements

How to model trunnion and lateral tees

How to model pressure vessels and columns connection: modeling local and global flexibility, WRC 297, WRC 537, FEA

How to model storage tank connection (API 650)

How to model connection to air cooled heat exchanger API 661, fired heater API 560, API 530

How to model connection to Pump, Compressor, Turbine (API 610, API 617, NEMA SM23)

How to model buried pipelines: Submerged Pipelines, Long Radius Bends Modeling of Laying, Lifting, Subsidence, Frost Heaving, Fault Crossing, Landslide

Underground piplines Seismic Wave Propagation, Pipe Buckling, Upheaval Buckling, Modeling of Pipe in Chamber, in Casing with Spacers. Electrical Insulation kit

Minimum design metal temperature calculation MDMT calculation, impact test

Modeling of Expansion Joints, Flexible Hoses, Couplings

Import and export to various software: CAESAR II, AVEVA, REVIT, PCF format, etc.

How to do Normal Modes Analysis and how to interpret results

ASME B31G Remaining Strength of Corroded Pipeline Calculation

Requirements

No requirements to attend the course

Description

This course created by experienced piping stress analysis specialists covers all features of onshore above ground and underground piping and pipeline analysis. The course is based on PASS/START-PROF software applying, though it will be valuable for users of any other pipe stress analysis tools as it contains a lot of theoretical information.Who should attend: process, piping and mechanical engineers specialized in design and piping stress analysis for the specified industries:Oil & Gas (Offshore/Onshore)Chemical & PetrochemicalPower (Nuclear/ Non-Nuclear)District Heating/CoolingWater treatmentMetal industryTraining software: all trainees are provided with a free 30-days PASS/START-PROF license.Certificate: After finishing the course you will receive the certificate from udemy and also certificate from PASS.PASS/START-PROF provides comprehensive pipe stress analysis with related sizing calculations according to international and national codes and standards. First introduced in 1965, PASS/START-PROF combines a highly efficient solver, powerful analysis features, very friendly and easy user GUI, an intuitive 3D graphical pre/post-processor, and a detailed help system with embedded intelligence from generations of piping design experts.Course consists of pre-recorded video lectures, quizzes, examples and handout materials. Section 1. Working with PASS/START-PROF User Interface 339 minSection 2. Piping Supports 138 minSection 3. Stress Analysis Theory and Results Evaluation 237 minSection 4. Underground Pipe Modeling 249 minSection 5. Static and Rotating Equipment Modeling and Evaluation 244 minSection 6. Expansion Joints, Flexible Hoses, Couplings 106 minSection 7. Non-Metallic Piping Stress Analysis 99 minSection 8. External Interfaces 65 min

Overview

Section 1: Working with PASS/START-PROF user interface

Lecture 1 Creating the New Project

Lecture 2 Creating the Simple Piping System

Lecture 3 3D Graphics Window

Lecture 4 Modifying the piping model

Lecture 5 Units. Renumber Nodes. List of Components

Lecture 6 Material, Insulation, Pipe & Component Databases

Lecture 7 Valve modeling (2-way, 3-way, 4-way, with drive), Flange Leakage Check

Lecture 8 Operation Mode Editor

Lecture 9 Load Case Templates

Section 2: Piping Supports

Lecture 10 Restraint Types in START-PROF

Lecture 11 Limit stop, Trunnion on the Bend

Lecture 12 Restraint choosing philosophy, roller support

Lecture 13 Spring Hanger Selection

Section 3: Stress Analysis Theory and Results Evaluation

Lecture 14 Stress Analysis Results. Support Loads, Displacements, Wall thickness

Lecture 15 Load and Stress types. ASME B31.1, B31.3, B31.5, B31.9 Strength Criteria

Lecture 16 Appendix V. Creep effect. Strength check summary ASME B31.1, B31.3, B31.5, B31.9

Lecture 17 Bourdon effect. Restrained and unrestrained pipes. ASME B31.4, B31.8, B31.12

Lecture 18 Stress intensification factors. ASME B31J. FEA. Lateral tee, trunnion

Lecture 19 Minimum design metal temperature calculation (MDMT)

Section 4: Underground Pipe Analysis

Lecture 20 Buried pipelines Modeling. Soil Properties

Lecture 21 Pipe-soil Interaction Model. Bending, Sliding, and Restrained Zones

Lecture 22 Specific Behavior of Buried Pipelines. Methods of Thermal Expansion Compensation

Lecture 23 Ring Bending Stress. Stress in Insulation. Stress from Surface Load. Long Radius

Lecture 24 Landslide. Seismic Wave Propagation. Pipe Wall Buckling, Upheaval Buckling. Mode

Section 5: Static and Rotating Equipment Modeling and Evaluation

Lecture 25 Connection to pressure vessels

Lecture 26 Stress and flexibility calculation per WRC 297/107/537/PD 5500/FEM

Lecture 27 Connection to the horizontal vessels and columns. Connection to the storage tank

Lecture 28 Connection to fired heater, air cooled heat exchanger, Pump, Compressor, Turbine

Section 6: Expansion Joints, Flexible Hoses, Couplings

Lecture 29 Expansion Joints Properties and Behavior

Lecture 30 Expansion Joint Types

Section 7: Non Metallic Piping Stress Analysis

Lecture 31 HDPE, PVC, PP Thermoplastic Piping Stress Analysis

Lecture 32 FRP/GRP/GRE Piping Stress Analysis

Section 8: External Interfaces

Lecture 33 Import from PCF, Import from Excel, API

Lecture 34 MS Word, Neutral file, Autocad, BMP, Jpg, PCF, CAESAR II

Lecture 35 Import from AVEVA PDMS, E3D, MARINE into START-PROF and backward

Lecture 36 Import from AUTODESK REVIT into PASS/START-PROF

Lecture 37 Export and Import from PCF into PASS/START-PROF

Section 9: Other

Lecture 38 Normal Modes Analysis

Lecture 39 ASME B31G Remaining Strength of Corroded Pipeline Calculation

Junior and experienced piping design engineers and pipe stress engineers

Screenshots

Homepage

without You and Your Support We Can’t Continue

Thanks for Buying Premium From My Links for Support

Click >>here & Visit My Blog Daily for More Udemy Tutorial. If You Need Update or Links Dead Don't Wait Just Pm Me or Leave Comment at This Post

Download from free file storage

Resolve the captcha to access the links!

Registered members don't get captcha ... just sayin